SHEAR BALERS

PCF LINE

The PCF LINE range of machineries includes stationary shear balers with shearing force up to 1400 tons meant to an hard work and to get high quality scrap, cleaned and with high density.

PCF shear balers are suitable for compressing and shearing any type of scrap from collected scrap, demolition, rebars, profiles, pipes, LCS to mixed, bulky scrap , all types of cyty scrap E.L.V.

All the models of the line can be mounted on support structures divided in two main pieces connected, therefore are not required foundation works to be installed.

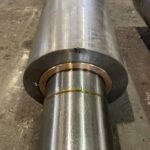

Shear Balers PCF boast widely dimensioned structures and main components all mechanically machined on high precision machining centers.

MAIN FEATURES

| PCF 650 | PCF 850 | PCF 1200 | PCF 1400 | |

|---|---|---|---|---|

| SHEAR | ||||

| Cutting force | 650 ton | 850 ton | 1200 ton | 1400 ton |

| Clamp | 90 ton | 150 ton | 180 ton | 200 ton |

| Knives width | 1000 mm | 1100 mm | 1100 mm | 1200 mm |

| CHARGING BOX | ||||

| Cover force | 250 ton | 400 ton | 450 ton | 480 ton |

| Charging box lenght | 6000 mm | 7000 mm | 7000 mm | 8000 mm |

| Charging box width | 2400 mm | 2800 mm | 3200 mm | 3400 mm |

| Bale dimension | 600x880 mm | 600x880 mm | 700x1000 mm | 700x1000 mm |

| Main compression cylinder | 150 ton | 210 ton | 250 ton | 280 ton |

| INSTALLED POWER | ||||

| Electric motors | 150 kw | 225 kw | 225 kw | 300 kw |

| Total installed power | 160 kw | 250 kw | 250 kw | 350 kw |